Edo Floats Maintenance Manual

- As a Cessna Service Station for single engine aircraft our inventory consists primarily of Cessna spares. We are seaplane and ski-plane specialists and have replacement parts for EDO, Wipline, CAP & PK floats and Federal Skis. We are a factory authorized Cessna Service Station and Parts distributor for Cessna Single Engine aircraft.

- Tractor Service Manuals: Kubota B1550 B1750 B2150 (HST) Tractors Service Repair Manual. Kubota B1700 B2100 B2400 Series Tractor Service Repair Manual. Kubota B1710, B2110, B2410, B2710 Tractor Service Repair Manual. Kubota B2410 B2710 B2910 Tractor Service Repair Manual. Kubota B1830, B2230, B2530, B3030 Tractor Service Repair Manual.

- This manual covers the installation and maintenance of the 2200 floats as installed on the PA-18 Piper Super Cub airplane (and similar models), including instructions for installing the struts, steps, water rigging, and float structure. An IPC is also provided. How to Use This Supplemental Manual.

What would 1320 Edo floats for a J3 sell for? I am looking at a J3 with floats and wheels and I wonder what I might be able to sell the floats for if I bought the plane.

Many of you who are regular visitors will know of my interest in this oft-maligned aircraft, and the men who flew it. I am pleased to offer this page with photos from varied sources, including a treasure trove from the Boeing Archives courtesy Dan Johnson. Other valuable contributions have been made by historians William T. Larkins (who actually took the photos he sent...what a wonderful era that must have been) and Mark Horan, co-author of A Glorious Page in our History

I intend to integrate the BuNo database and photo page into a single, searchable entity at some point in the future for added convenience. I would also like to invite any submissions from visitors who may have photos of TBDs, as well as any feedback you may have. Thanks for visiting!

Action and service photos

The VT-2 photos below are taken from one group photo (SM23964-TBD-1-6-41) over California on 6 January 1941. Interestingly, this photo has four future VT-8 aircraft in the formation. This is the second-largest airborne shot of VT-8 aircraft in formation that I am aware of; the largest being a picture of the entire squadron passing over Hornet on the way to attack the Kido Butai on 4 June 1942 shortly after 9 AM local time.

The following images were recently made available via the Photographic Section at www.history.navy.mil (an outstanding resource, for those who are unfamiliar with that site). I cannot emphasize how pleased I am to see these photos readily available in the public domain, and offer my thanks to the individual or group responsible for compiling and scanning this photo collection! Each photo has a brief explanation in the caption. Additionally, links are provided to identified aircraft through the data page (e.g. BuNo '0333' being jettisoned from the Yorktown). NOTE: This is not, repeat, NOT, BuNo 0333. I am still trying to determine exactly which aircraft this is, but I know for a fact it's not 0333 asI received a letter from one of the two men who would know best...Ray Machalinski, the gunner who took a swim along with his pilot, Lt. Leonard Ewoldt when they ditched BuNo 0333 after the Tulagi raid on May 4, 1942. More details as they become available!

These photos illustrate theapplication of the experimental Barclay camouflage scheme to two VT-3 aircraft,BuNos 0320 and 0339 (3-T-7?). The photos were taken at NAS North Island, San DiegoCA on 22 Aug 1940.

BuNo 0320, Barclay 7:

BuNo 0339, Barclay 8:

The TBD in Color

The Devastator was the Navy'sfirst monoplane to see squadron service, and as such was afforded quite a bit ofpress in its day. Fortunately, some of the photos taken were shot incolor, giving us an opportunity to see those Golden Wings the way they weremeant to be seen!

| These three photos are part of aspecial color centerfold feature shot aboard CV-6 Enterprise in eitherlate 1940 or early 1941 which appeared in the March 31, 1941 edition ofLIFE. VT-6 was one of the earliest adopters of the Navy's new all-greycamouflage scheme directive issued in January 1941, as evidenced by theirappearance in the Warner Brothers' classic movie 'Dive Bomber'. |

| This somewhat pixelated Rudy Arnold shot appeared in the February 1942 edition of 'Flying' magazine. |

| Another shot from the incomparable Rudy Arnold, this shows a TBD attached to VS-42 aboard USS Ranger on patrol along the Eastern seaboard (most likely off Norfolk) sometime in 1941. |

Accident photos

Other assorted photos

Color profiles and Squadronemblems

(A word about the profiles: Iam most certainly NOT Tom Tullis or Claes Sundin, so please excuse the basicappearance of these!) These are just to give an idea of how the aircraftlooked at a given time, and salient features are captured as best aspossible. This will be a large project, and will eventually be categorizedin a searchable database by four digit BuNo. This section is currentlyunder development...below is the first 'base profile' for the GoldenWings versions as it appears under development.

Walkaround photos

The majority (if not all) of these photos are ofBuNo 0268, the first production Devastator, and were taken throughout 1937 atthe Douglas factory in Santa Monica (judging by the background). Thisaircraft was subsequently retained for testing by the Navy, later being fittedwith Edo floats as the TBD-1A. Further details are available on the datapage; the aircraft was unceremoniously scrapped on 22 September 1943.

Interior photos

Well, if you can't do a Devastatorwith THESE photos, I don't know what else to tell you. :-) Most ofthese are scanned from original Douglas factory photographs; a couple come fromthe Erection and Maintenance manual, and these are of a slightly fuzzy quality,that's just how they are in the book. Now, the only thing we need arecolor photos...

Pilot's Cockpit:

Bomb and torpedo aiming position:

Gunner/radioman position:

Exterior details:

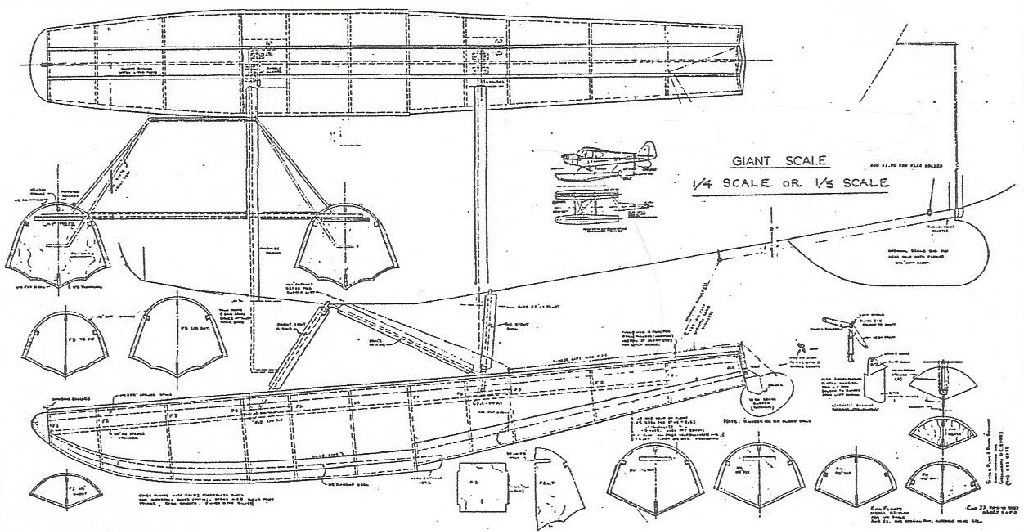

Technical drawings

Thanks to the unparalleledgenerosity of a fellow modeler, I am now in possession of an Erection andMaintenance Manual for the TBD-1 as well as the Pilot's Notes and an enginemanual..

Floats

Corrugated Skin Repair

Figure 2. Beaded skin repair on corrugated surfaces |

Replacement of a Panel

Figure 3. Replacement of an entire panel |

Outside the Member

Inside the Member

Edges of the Panel

Repair of Lightening Holes

Repairs to a Pressurized Area

The skin of aircraft that are pressurized during flight is highly stressed. The pressurization cycles apply loads to the skin, and the repairs to this type of structure requires more rivets than a repair to a nonpressurized skin. [Figure 5]Figure 5. Pressurized skin repair |

- Remove the damaged skin section.

- Radius all corners to 0.5-inch.

- Fabricate a doubler of the same type of material as, but of one size greater thickness than, the skin. The size of the doubler depends on the number of rows, edge distance, and rivets spacing.

- Fabricate an insert of the same material and same thickness as the damaged skin. The skin to insert clearance is typically 0.015-inch to 0.035-inch.

- Drill the holes through the doubler, insertion, and original skin.

- Spread a thin layer of sealant on the doubler and secure the doubler to the skin with Clecos.

- Use the same type of fastener as in the surrounding area, and install the doubler to the skin and the insertion to the doubler. Dip all fasteners in the sealant before installation.

Stringer Repair

Edo Floats Maintenance Manual Diagram

Figure 7. Stringer repair by patching |

Figure 8. Stringer repair by insertion when damage exceeds two-thirds of one leg in width |

Figure 9. Stringer repair by insertion when damage affects only one stringer |

Figure 10. Stringer repair by insertion when damage affects more than one stringer |

Former or Bulkhead Repair

Figure 11. Bulkhead repair |

- Stop drill the crack ends with a No. 40 size drill.

- Fabricate a doubler of the same material but one size thicker than the part being repaired. The doubler should be of a size large enough to accommodate 1⁄8-inch rivet holes spaced one inch apart, with a minimum edge distance of 0.30-inch and 0.50-inch spacing between staggered rows. [Figure 12]

- Attach the doubler to the part with clamps and drill holes.

- Install rivets.

Edo Floats Maintenance Manual Transmission

Edo Floats Maintenance Manual Pdf

Edo Floats Maintenance Manual Instructions

RELATED POSTSBasic Principles of Sheet Metal Repair

Repairability of Sheet Metal Structure

Approval of Repair

Typical Repairs for Aircraft Structures - Longeron-Spar-Rib and Web-Leading Edge-Trailing Edge-Specialized Repairs-Inspection Openings